Stochastic & Conventional Screening

Discover How the Right Screening Can Transform Your Printed Images.

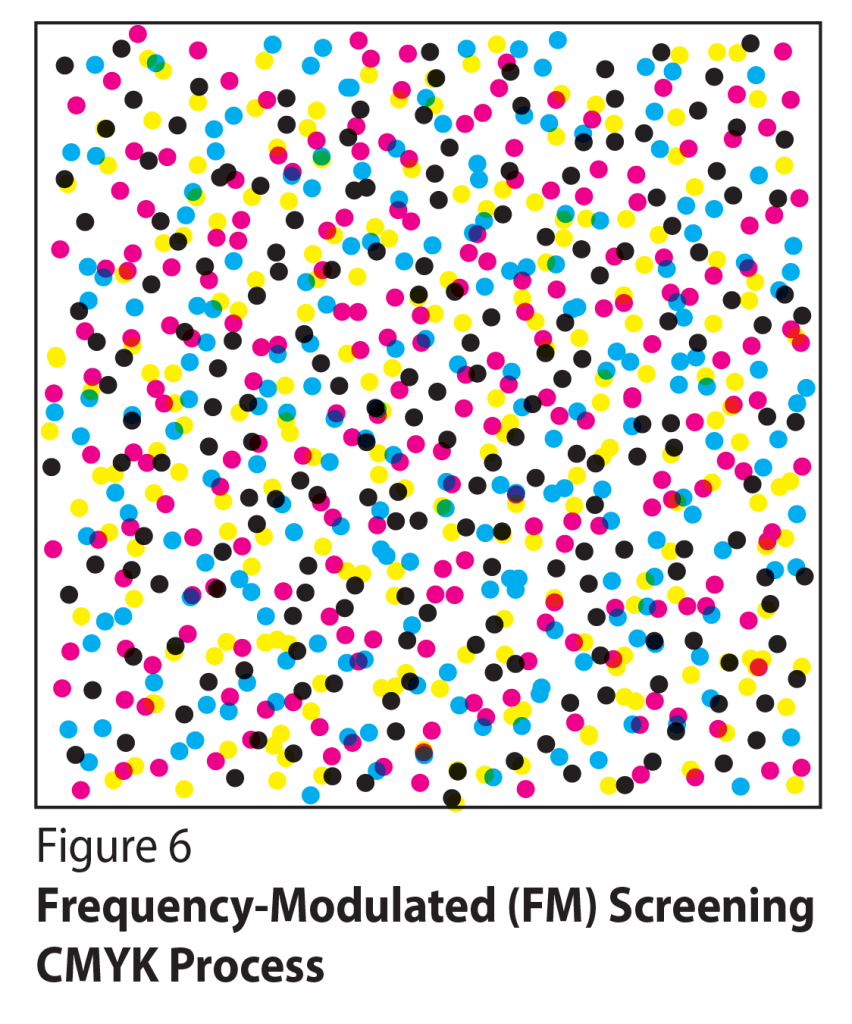

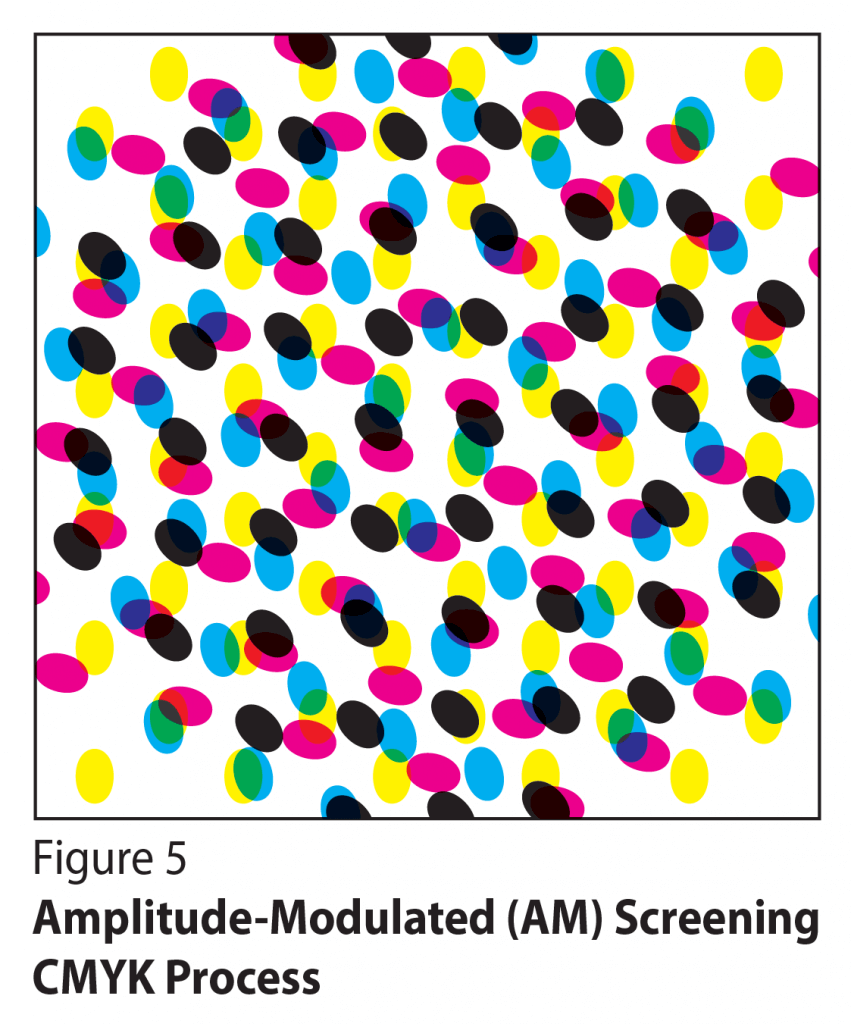

- Conventional (AM) Screening: Uses rows of equally spaced dots that vary in size to reproduce tonal values. It’s great for consistent, reliable results, especially in legacy or high-volume print jobs.

- Stochastic (FM) Screening: Uses a randomized dot pattern where all dots are the same size but vary in placement. This results in sharper images, smoother gradations, and better detail in highlights and shadows.

Understanding Dot Screening: Stochastic vs. Conventional

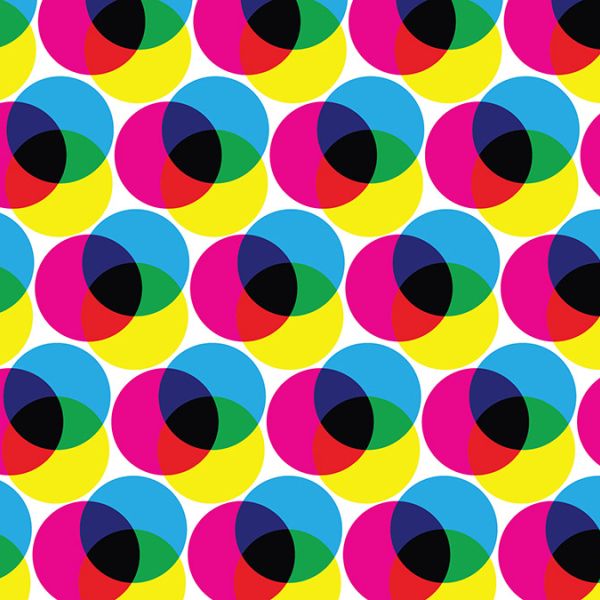

Dot screening is the process that determines how images are reproduced in print using tiny patterns of ink dots. The choice between stochastic (FM) and conventional (AM) methods can significantly impact how sharp, smooth, and clean your images appear. AM screening arranges dots in a consistent grid and adjusts their size to depict tones, while FM screening places same-sized dots in a randomized pattern. Recognizing the strengths and limitations of each can help guide better printing outcomes based on your unique goals.

Why Dot Size and Placement Matter

The characteristics of the dot pattern—its size and spacing—can influence how much depth, resolution, and smoothness your final printed image will show. Smaller dots, like those used in FM screening, allow for greater tonal control and more seamless gradients, particularly in areas like skies, skin, or shadows. The pattern’s arrangement also plays a key role in whether visual distortions appear, especially when printing fine patterns or overlapping textures. Understanding these mechanics is essential to avoiding print flaws and getting high-quality, lifelike results.

- Smaller Dots, Greater Detail: Stochastic dots are much smaller—typically 24 microns—compared to conventional 150-line screens.

- Random vs. Regular Patterns: FM’s randomness eliminates moiré and banding, offering a photographic look. AM screens can struggle with these issues in high-res or metallic images.

- Texture Matching: FM screens are ideal for textured surfaces (fabric, hair, metal) and preserve intricate details.

- Color Consistency: Stochastic printing makes colors line up better and helps smooth out color changes.

Visual Texture and Color Accuracy

How a print captures texture and manages color transitions can make or break its impact, particularly in detailed or artistic projects. Stochastic printing keeps textures looking accurate because its random dot pattern avoids visual glitches that can happen with regular dot layouts. Additionally, the even distribution of FM dots helps ink lay down more consistently, leading to smoother color transitions and more vibrant visual results. These features are especially beneficial when printing materials that require high realism and tonal variation.

Where Each Technique Excels

Each dot screening method has ideal use cases depending on your project type and print goals. AM screening’s reliable structure makes it a strong choice for applications with simple design requirements. Meanwhile, FM screening shines when precision, subtlety, and visual richness are critical—like in photography, fine art, or luxury packaging. Knowing which approach is right for your job can help you save time, reduce cost, and improve final output quality.

- AM Screening: Best for uniform designs such as stationery, letters, and envelopes.

- FM Screening: Preferred for detailed designs such as photography, art prints, and packaging.

How Phillips Printing Can Help

Phillips Printing is equipped to guide clients through selecting the ideal dot screening technique for their specific print needs. Whether you require the crisp clarity of stochastic screening or the reliable uniformity of conventional halftone, our advanced offset and digital presses, combined with expert press operators, ensure top-tier print quality. We also provide test proofs, paper recommendations, and side-by-side comparisons so you can be confident in your results before going to the press.

Testimonials

- “The clarity from stochastic printing blew us away. Phillips walked us through every step.” – Carla

- “We’ve used both methods, and Phillips made sure we picked the right one for each project.” – Dean

- “Their color matching and attention to detail using FM screening gave our campaign an edge.” – Liz

Case Study

A high-end photography studio approached Phillips Printing to produce a limited-edition art book. Conventional screening failed to capture the detail in hair textures and skin tones. By switching to 24-micron stochastic screening, Phillips delivered prints with rich, true-to-life color and immaculate texture reproduction—earning the studio a print industry award for excellence.

Did You Know?

Stochastic screening can reduce ink usage by up to 10% compared to traditional halftone printing. This efficiency not only lowers printing costs but also enhances color saturation and consistency across print jobs. The smaller, randomly placed dots in stochastic screening allow for more uniform ink distribution, minimizing the “whiteness” of the paper showing through and resulting in more vibrant images.

Sources: Brumley Printing