Protective Coatings and Laminates for Printed Materials

Protect What You Print.

Understanding Protective Coatings

Protective coatings are essential in preserving the integrity and appearance of printed materials. They serve as a barrier against environmental factors, handling, and wear, ensuring that your prints maintain their quality over time. By selecting the appropriate coating, you can enhance the visual appeal and longevity of your printed products. Phillips Printing’s commitment to clear, consistent communication ensures clients receive guidance in choosing the best coating for every job.

- Varnish: A traditional, cost-effective coating that adds a subtle sheen and basic protection.

- Aqueous Coating: A water-based option that dries quickly, offering a smooth finish and resistance to smudges and fingerprints.

- UV Coating: A high-gloss finish cured by ultraviolet light, providing superior durability and vibrant color enhancement.

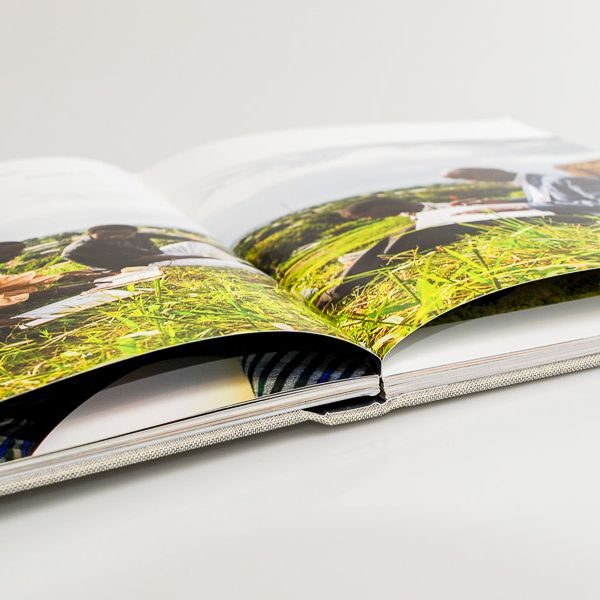

Exploring Lamination Options

Lamination involves applying a thin film to printed materials, offering enhanced protection and a premium feel. This process not only safeguards against physical damage but also adds a tactile dimension to your prints. Choosing the right laminate can significantly impact the functionality and perception of your printed pieces. The team at Phillips Printing ensures a smooth, low-stress process for selecting and applying lamination that meets both your aesthetic and practical needs.

- Gloss Laminate: Provides a shiny finish that enhances color vibrancy and visual appeal.

- Matte Laminate: Offers a non-reflective, elegant finish ideal for a sophisticated look.

- Soft-Touch Laminate: Soft-Touch Laminate: Delivers a velvety texture, adding a luxurious feel to printed materials.

Benefits of Coatings and Laminates

Applying coatings and laminates to printed materials offers numerous advantages beyond mere aesthetics. These protective layers extend the lifespan of prints, maintain their appearance, and can even contribute to environmental sustainability. Understanding these benefits can help in making informed decisions for your printing projects.

- Sustainability: Some coatings are environmentally friendly, reducing ecological footprints.

- Durability: Protects against scratches, moisture, and handling damage.

- Enhanced Appearance: Improves color depth and overall visual impact.

Applications in Various Industries

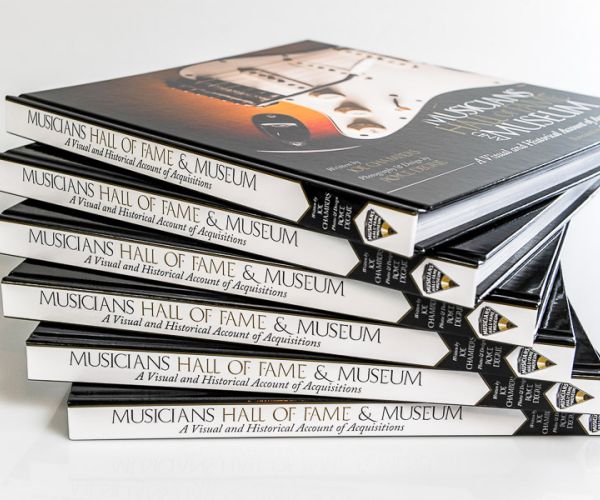

Protective coatings and laminates are utilized across multiple industries to ensure printed materials withstand specific environmental and usage conditions. From packaging to promotional materials, the right protective finish can make a significant difference. Tailoring the choice of coating or laminate to the intended application ensures optimal performance and longevity.

- Packaging: Enhances shelf appeal and protects contents during transit.

- Marketing Materials: Maintains professional appearance through repeated handling.

- Educational Resources: Ensures longevity of frequently used materials like manuals and textbooks.

How Phillips Printing Can Help

At Phillips Printing, we understand the importance of protecting your printed materials. Our expertise in applying various coatings and laminates ensures that your projects not only look exceptional but also stand the test of time. We offer personalized consultations to determine the best protective solutions tailored to your specific needs, ensuring your prints achieve both aesthetic and functional excellence.

We specialize in supporting clients with medium to large-volume printing needs, providing dependable, consistent results across every project. If your priority is high-quality work delivered reliably, not just low cost—you’ll find a trusted partner in Phillips Printing.

Testimonials

- “Phillips Printing transformed our brochures with their protective coatings, and now they last longer and look better.” – Emily

- “The soft-touch laminate added a premium feel to our business cards.” – Michael

- “Their team guided us to the perfect coating choice for our catalogs.” – Samantha

Case Study

EcoPack Solutions sought sustainable packaging that didn’t compromise on durability or visual appeal. Phillips Printing recommended an aqueous coating for its eco-friendly properties and effective protection. The resulting packaging met sustainability goals and impressed customers with its quality finish.

Did You Know?

Water-based aqueous coatings are not only effective in protecting printed materials but also align with environmental sustainability goals. According to Scalable Press, aqueous coatings are considered eco-friendly and provide resistance to scratches and moisture, making them a smart choice for both performance and the environment.

Sources: Scalable Press