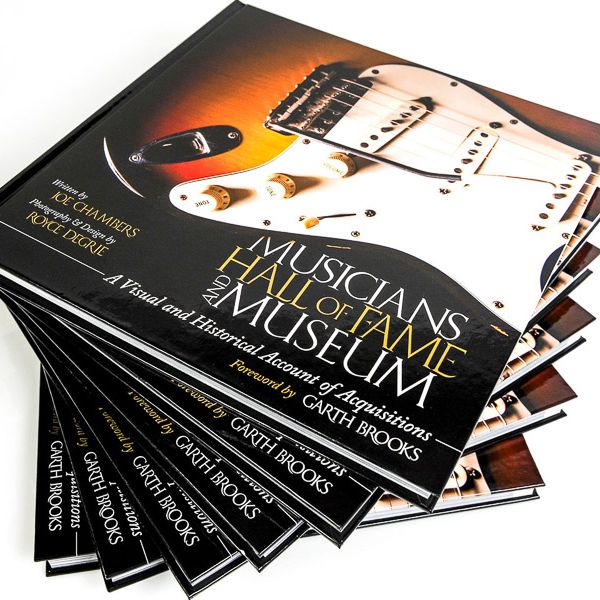

Understanding Print Quality

Print quality refers to the clarity, detail, and precision of printed images or text on a physical surface. It covers sharpness, color accuracy, and the absence of flaws to ensure that every piece meets the intended purpose. High-quality printing often aims for photorealism in image reproduction, though the concept extends to broader elements such as durability and consistency. When done well, print quality reinforces trust and ensures that printed materials achieve their intended purpose with clarity and impact.

- Color Accuracy: Achieving color fidelity starts with understanding color theory, light interactions, and ink behavior across substrates.

- Image Composition: Optimal use of image resolution, contrast, and layout enhances readability and visual impact.

- Halftone and Screening: Halftoning breaks down images into patterns of dots, while screening methods influence detail and smoothness.

- Finishing Techniques: Post-press finishes like coatings, embossing, or laminating can elevate a printed piece’s appearance and durability

Critical Factors In Print Quality

Many technical and process-related variables influence how well a print product turns out. From alignment to ink control, each factor contributes to clarity and overall impression. Consistency is especially important when producing large volumes of materials that must maintain the same high level of quality throughout. At Phillips Printing, our priority is to ensure projects remain stress-free while delivering excellent outcomes.

- Registration Accuracy: Aligning multiple layers of color must be precise to avoid blurring or ghosting.

- Dot Gain: Careful management of dot gain helps avoid unintended darkening, keeping tones accurate and balanced.

- Ink Trapping: Effective ink trapping allows successive colors to adhere cleanly, maintaining crisp edges and smooth transitions without misregistration.

- Surface Finishing: Finishes such as gloss, matte, and texture affect both feel and function.

- Environmental Conditions: Temperature, humidity, and press maintenance all affect ink transfer and paper behavior.

Measuring And Controlling Print Quality

The ability to measure and regulate print quality ensures consistency across every job. Modern tools allow for precise monitoring of color, density, and gloss. Automated systems now make it possible to detect errors in real time, reducing waste and maintaining high standards.

- Spectrophotometry: Measures color values to ensure accurate reproduction.

- In-line Quality Control: Automated sensors on presses detect and correct color shifts, misalignment, and density variations in real time.

- Gloss Measurement: Ensures surface appearance aligns with client expectations.

Impact Of Print Methods On Quality

Different printing processes have distinct strengths and challenges that affect final results. Offset printing, gravure, and letterpress each bring unique advantages, whether the goal is sharp impressions, smooth gradients, or long-run consistency. Choosing the right method ensures that the printed material achieves its intended purpose with excellence. Phillips Printing focuses on helping clients choose the process that balances both quality and reliability over simply cost.

- Offset Printing: Offers exceptional color stability and detail, with advanced in-line quality control tools.

- Gravure Printing: Ideal for high-volume, high-resolution applications such as packaging and magazines.

- Letterpress: Produces crisp text and deep impressions, often used for premium invitations and stationery. .

How Phillips Printing Can Help

At Phillips Printing, we specialize in achieving and maintaining exceptional print quality for medium to large-volume projects. Our investment in advanced print technology—like inline spectrophotometric control systems and automated register correction—ensures every job is consistent, precise, and visually compelling.

We are committed to making each project smooth and stress-free for our clients while delivering outcomes they can be proud of. With an emphasis on quality and dependability rather than simply being the lowest-cost provider, we give clients confidence in the final result. Our clients also appreciate our hands-on service and transparent communication, which make the entire process easier and more collaborative.

Testimonials

- “I couldn’t believe the color accuracy. Phillips nailed it on every piece. A true partner in our print success.” – Emily

- “Their print quality turned our ordinary brochure into a premium marketing tool.” – Jordan

- “The consistency across our product line packaging was flawless. Phillips Printing really delivered.” – Marcus

Case Study

A regional health system required information packets with precise brand color matching and durability through repeated handling. Phillips Printing deployed inline color control and durable aqueous coatings, ensuring vibrant, uniform quality across every unit. The result? Zero reprints, accelerated delivery, and rave feedback from both the client and patients.

Did You Know?

A handy rule of thumb: images printed at roughly 240–300 PPI generally appear “photo-quality” at normal reading distances. Going far above that range yields diminishing returns compared to dialing in color management and press control—so the right resolution plus consistent process beats sheer pixel count.

Sources: How Stuff Works