What Are Metallic Inks?

Metallic inks are specialty printing inks that contain metal particles to reflect light and create a shimmering, eye-catching effect. They stand out from traditional inks by offering depth and luminosity that instantly draw the eye. As a result, they’re often used in designs where premium presentation matters. At Phillips Printing, our clients value the consistent, high-quality output we provide with specialty applications like metallic ink.

- Ink Composition: Created by blending metal flakes like aluminum or bronze into a base ink.

- Unique Look: Provides a glossy, reflective finish unlike standard CMYK inks.

- Popular Uses: Premium packaging, invitations, high-end marketing materials, and magazines.

Getting The Most From Metallic Inks

Working with metallic inks isn’t just about selecting the right color—it’s a creative and technical process that requires the right tools, techniques, and planning. Designers must understand how these inks behave on press, how different papers absorb or reflect light, and how coatings interact with metallics. From simple enhancements to complex multi-layer blends, the decisions made during design and prepress can dramatically impact the final look. Phillips Printing supports clients through every step, offering clear communication and hands-on advice to ensure results exceed expectations.

- Understanding The Basics: Learn how metallic inks behave with different paper stocks, coatings, and trapping conditions.

- Build With Contrast: Use halftones, duotones, tritones, and graphic solids to enhance shine and tonal variation.

- Advance With Blending: Create high-impact results using touch plates, multi-color blends, and varnish layering techniques.

Technical Considerations For Metallic Inks

Success with metallics demands precision and planning. The substrate, coating method, and press technique all contribute to the final result. Decisions made early in the design process will greatly affect visual quality and longevity. Plan ahead for optimal metallic performance through informed material selection and early design decisions.

- Paper Types: Coated gloss papers reflect more light and enhance shine.

- Coatings and Varnishes: Dry trapping, gloss vs. dull, and aqueous coatings protect and enhance luster.

- Screening Challenges: Small halftone dots diminish metallic impact—plan for solid fills when possible.

Design Strategies For Metallic Effects

Metallics can be strategically used for both subtle enhancement and bold statements. By layering inks, designers can achieve entirely custom hues and finishes. Special considerations for legibility and ink behavior make it important to prototype and proof early. Explore proven techniques to maximize visual impact while maintaining design clarity.

- Type and Reverses: Use sparingly to avoid legibility issues due to ink opacity.

- Color Mixing: Blend metallics with other inks or overlay for customized hues.

- Touch Plates: Add drama and depth by layering metallic touch plates over or under standard CMYK.

How Phillips Printing Can Help

Phillips Printing specializes in advanced print techniques, including metallic ink applications that elevate your materials with shimmering detail and professional polish. Our expertise in prepress preparation, ink selection, and coating options ensures that your metallic projects pop—without compromising quality or production efficiency. We prioritize smooth, low-stress project workflows and provide hands-on support for every phase of your print job.

Our medium- to large-volume capabilities make us an ideal choice for businesses that demand consistent excellence. Most importantly, we serve clients who value quality and reliability above all else. Phillips Printing is known for maintaining consistent communication throughout the print process to keep your projects on track. We work closely with your team to ensure a collaborative experience, emphasizing dependable outcomes. Our clients know they can count on us to deliver what we promise—on time, every time.

Testimonials

- “Our brochures had just the right amount of shimmer — clients are still talking about it!” – Lisa

- “Phillips walked us through every step. The metallic finishes made our brand feel premium.” – Marcus

- “Great print quality and the gloss varnish on metallic ink gave our pieces a beautiful, subtle shine.” – Tina

Case Study

A brand needed premium packaging to stand out on crowded shelves. Phillips Printing used metallic silver inks and gloss varnishes on coated stock to create high-impact visuals. The result was an increase in shelf recognition and positive consumer feedback.

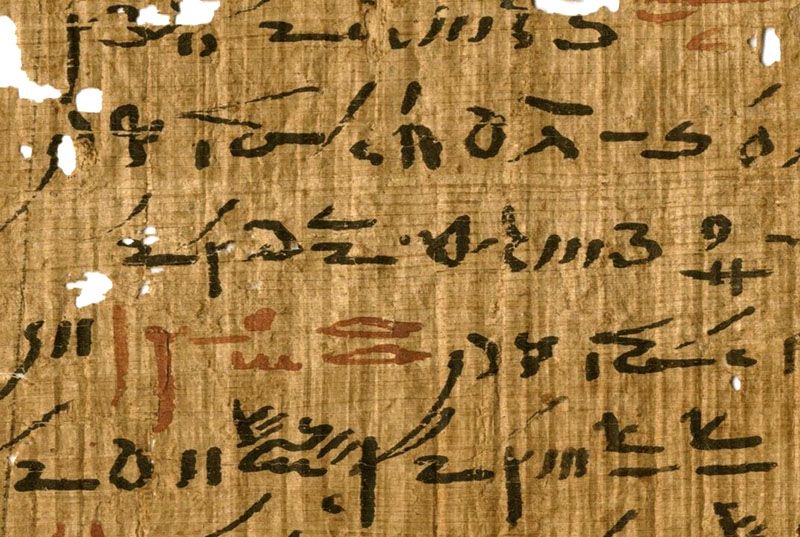

Did You Know?

Ancient Egyptian scribes used copper-infused inks in their papyri for over three centuries—some documents dating as far back as 88 BCE still carry ink containing copper minerals like cuprite and malachite, showcasing one of humanity’s earliest uses of metallic inks for written communication.

Source: Cosmos Magazine