Understanding Folding

Folding plays a vital role in print production by converting flat sheets into functional, structured formats. It allows printed materials to be transformed into brochures, multi-panel layouts, or signatures for bookbinding. Folded formats support visual storytelling, organization, and efficiency in design. Selecting the right folding technique ensures accuracy in layout, readability, and aesthetic appeal.

- Parallel folds like concertina (zig-zag), letter (tri-fold), and gatefold (double gatefold) organize content into consecutive, engaging panels.

- Right-angle folds, such as cross folds, reduce large printed sheets into manageable, portable sizes.

- Combined fold sequences can create compact 12- to 32-page booklets used for catalogs or inserts.

- Two-up impositions like “genuine” and “come and go” layouts maximize sheet usage and enhance production speed.

- Signatures are grouped folded sheets that enable correct collation in bookbinding workflows.

Technology Behind The Fold

Modern folding systems combine mechanical precision with intelligent planning to deliver clean, accurate results. Equipment choices and layout programming directly impact production quality. Folding machines offer modular capabilities that align with folding complexity and volume needs.

- Buckle-fold units feed paper into buckle plates and rollers to produce fast, efficient folds for a variety of common applications.

- Knife-fold units use a tapered blade for higher precision and tighter tolerances, especially effective for thicker or coated paper stocks.

- Modular machines can be configured with removable buckle plates, knife shafts, and feeders to match specific folding requirements.

- Advanced software stores fold patterns in master data files, streamlining setup and reducing manual programming.

- Imposition algorithms automate complex folding sequences, saving time and ensuring correct pagination.

- Rule-based programming accommodates custom layouts and complex signatures without interrupting workflow.

Flexibility and customization are core to seamless folding setups, and at Phillips Printing we value clear communication with clients to set up folding configurations that deliver consistent, dependable results. We make complex folds easy by ensuring each job runs smoothly with handson service from planning to delivery.

Fold Types That Make An Impact

Not all folds are created equal—each has unique strengths depending on the communication goal. Some enhance storytelling, while others condense information for convenience. Strategic fold selection adds tactile value to printed materials and guides how users engage with the content. Knowing when and how to use these folds is key to impactful design.

- Concertina (Zig-Zag): Ideal for panoramic layouts or sequential storytelling, this fold opens accordion-style for visual impact.

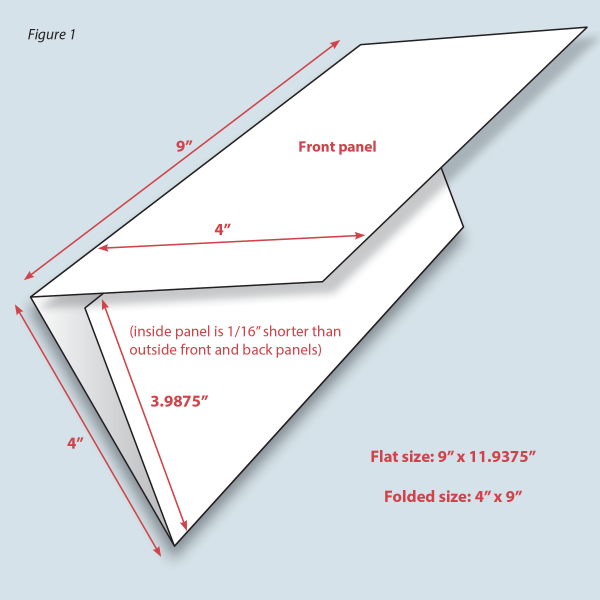

- Letter Fold (Tri-Fold): Common in brochures, it’s compact, easy to mail, and reveals information in controlled sections.

- Gate Fold: Perfect for dramatic reveals or showcasing a central visual, where the two ends fold inward to meet in the middle.

- Cross Fold: Often used in maps or posters, where right-angle folds reduce large prints to handheld size.

- Double-Parallel and Roll Folds: Used for educational materials or product explainers that require step-by-step flow.

When To Use Complex Folding Sequences

Some projects require more intricate folding combinations to meet layout, size, or binding needs. Complex folds help control reading flow, page sequence, or compactness in high-volume materials. Understanding when to incorporate layered folds can make production more efficient and materials more effective. This knowledge separates routine print jobs from exceptional ones.

- Two-Up Imposition: Used to print and fold two copies of a layout simultaneously—ideal for maximizing efficiency in booklet production.

- Asymmetrical Gate or Roll Folds: Useful when varying panel sizes are needed to prevent bulging or misalignment in thicker projects.

- Combination Folds (Parallel + Right-Angle): Essential for booklets ranging from 12 to 32 pages, maintaining page order and readability.

- Short Folds with Knife Units: Necessary for stiff or glossy stocks where buckle plates may fail to execute clean folds.

- Folding for Signatures: Required for books and catalogs to ensure proper collation and seamless binding later in production.

How Phillips Printing Can Help

At Phillips Printing, our handson service means we walk clients through each customization—whether developing a custom folding layout or integrating complex fold sequences like twoup “come and go.” We specialize in medium to largevolume jobs and tailor solutions for efficiency and accuracy. Our clients benefit from consistent, highquality results driven by welltuned folding modules and smart imposition planning. Reliability matters more than the lowest price, and our goal is to ensure every fold is precise and every project lowstress.

Using state-of-the-art buckle and knife folding units, we calibrate folding geometry and tension for smooth, markfree results across jobs. With advanced software tools, we help streamline folding workflows—so pages align perfectly, and signatures assemble without hassle.

Our commitment to consistency reflects our dedication to craftsmanship across every run. We treat your folding needs with the same care we’d give to our own—delivering quality and trust with every sheet.

Testimonials

- “The folding on our annual report came out flawless. Phillips Printing’s precision and communication made it all smooth.” – Sarah

- “Our brochures feature gate folds that turned out perfect, every time. Reliable and fast service!” – James

- “They handled a 20,000 piece project with tight fold tolerances and zero errors. Impressive consistency.” – Maria

Case Study

A non-profit commissioned a concertina brochure with multiple rightangle folds for event distribution. At scale, minor misalignment meant big trouble—but Phillips Printing integrated a combined buckleknife folding workflow, adjusted folding modules to tight specs, and used a custom computerized layout. The result: clean folds, accurate pagination, ontime delivery, and zero rewrites—simultaneously satisfying aesthetic and timing goals.

Did You Know?

The first U.S. patent for a paper folding machine was granted in 1849 to Edward N. Smith of Massachusetts, featuring a knife-folder design that resembles modern machines—utilizing a belt transporter feeding sheets to a knife and fold rollers to produce multiple folds.

Sources: In-plant Impressions